Who are we ?

It is in 1780 that Jean-Etienne Astier, first manufacturer of ochre, sets up an industrial process of separation of ochre and sand. Middle of the 19th century, the ochre industry is at its peak and ochre is exported worldwide.

rom 1875, the ore became increasingly scarce and expensive. It was necessary to move to underground extraction by wells and galleries. Operating costs are increasing.

After 30 years of almost monopoly, the ochre of Burgundy feels harshly the competition of the ochre of the Vaucluse, exploited in the open air in the communes of Gargas, Gignac, Mormoiron, Roussillon, Rustrel, Saint-Pantaléon, Villars and Villes-sur-Auzon. Several operators of Puisaye (Burgundy), including Gustave Parquin and George Lechiche, are convinced for a long time of the need to merge the different companies in one because of the competition of too many operators. They succeeded in convincing most of their confreres in two stages : by forming on May 1, 1892, the Comptoir des Ocres de Bourgogne, then the Société des Ocres de France in 1901.

While in 1929 there were still some 18 companies, employing nearly a thousand people and producing about 40,000 tonnes ; by 1931, the effects of the global economic and geopolitical crisis will have disastrous consequences on the ochre industry. The decline in ochre was caused by the arrival on the market of new products at the end of the 1940s : on the one hand, petroleum-derived products which replace ochre in the manufacture of rubber; on the other, synthetic pigments.

From the 1950s onwards, the ochre trade was weakened and factories starts to close one by one.. The Société des Ocres de France (SOF) keeps its course as well as it can. On October 31th 1973, the company filed an application for cessation of activity with virtually zero production and an empty order book.

But that was without counting the determination of a man : Gilbert Guigou. Born in Apt, mason, he has been using ochre for years and has always known this industry, present in his city. When he learned that the Société des Ocres de France was bankrupt and to be sold, he did not hesitate for long and invested his savings to buy it back in 1974. The factory is in ruins, the machines unusable. Patiently and with his head full of projects, he will restart production and find new markets.

Gilbert Guigou

In 1985, Jean-Paul and André, Gilbert’s sons, sell their masonry business to join their father. Jean-Paul took charge of the administrative part while André went towards manufacturing.

Nelly, André’s wife, puts her skills as a stenographer at the service of the company. Between the three of them, they found new contracts in the construction industry.

The company Strasservil, in full development, entrusts them with the manufacture of their whitewash. Other well-known companies in the paint industry also use their services. The Ocres de France and Lafarge plaster will even create together a range of colored plaster.

First range of lime coatings and limewashes in 1996

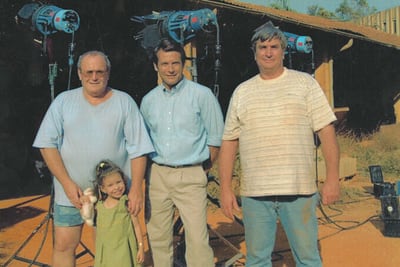

Jean-Paul (left), Laurent Bignolas - presenter of the TV program "Des Racines et des Ailes" (in the middle), André (right) and Ludivine

In 1996, 1998 and 2014, the grandchildren of Gilbert Guigou, Brice, Stéphanie and then Pascal joined the family business by choice and love of the profession. They have a common objective : to enhance and revitalize as much as possible this beautiful heritage of ochre.

Under the watchful eye of the elders, the family saga continues and extends over a fourth consecutive generation with the arrival in the company, in August 2019, of the great-granddaughter of Gilbert Guigou, Ludivine.

For years, the Société des Ocres de France remained in the shadows, almost ashamed to stand while so many others fell. "We had a small office in the factory and we didn’t really sell to individuals. As a result, we were unknown to the general public who thought we no longer existed or who confused our re-sellers with us," says Stéphanie Anglès-Guigou. To overcome this, the family decides to open a store on the main avenue of the city of Apt : this "showcase" will finally begin to highlight the company. Ten years later, for logistical reasons (storage capacity, communication problem between the sales team and production), Pascal, Brice and Stéphanie decided to build buildings directly inside the factory. Thus, in January 2015, the store team joined the production team. This initiative will be welcomed by customers who will find in the showroom a greater choice of products and timetables better adapted to craftsmen.

From left to right : Brice, Stéphanie and Pascal

"Today, we are proud of what we represent : French know-how, handed down from generation to generation, a noble product, an ecological industry, an international curiosity, an immense desire to make our industrial heritage flourish; not to get rich, but simply to make our grandfather proud of us and what we have accomplished. It’s a real challenge and we’ll get there" - Stéphanie Anglès-Guigou

Nowadays, Ocres de France is the last autonomous company in Europe that exploits and transforms ochre ore into pure ochre.

And speaking of that, do you know anything about ochre ? To discover more about this natural richness, its extraction and the different processing processes, we invite you to read "The manufacture of ochre" :)